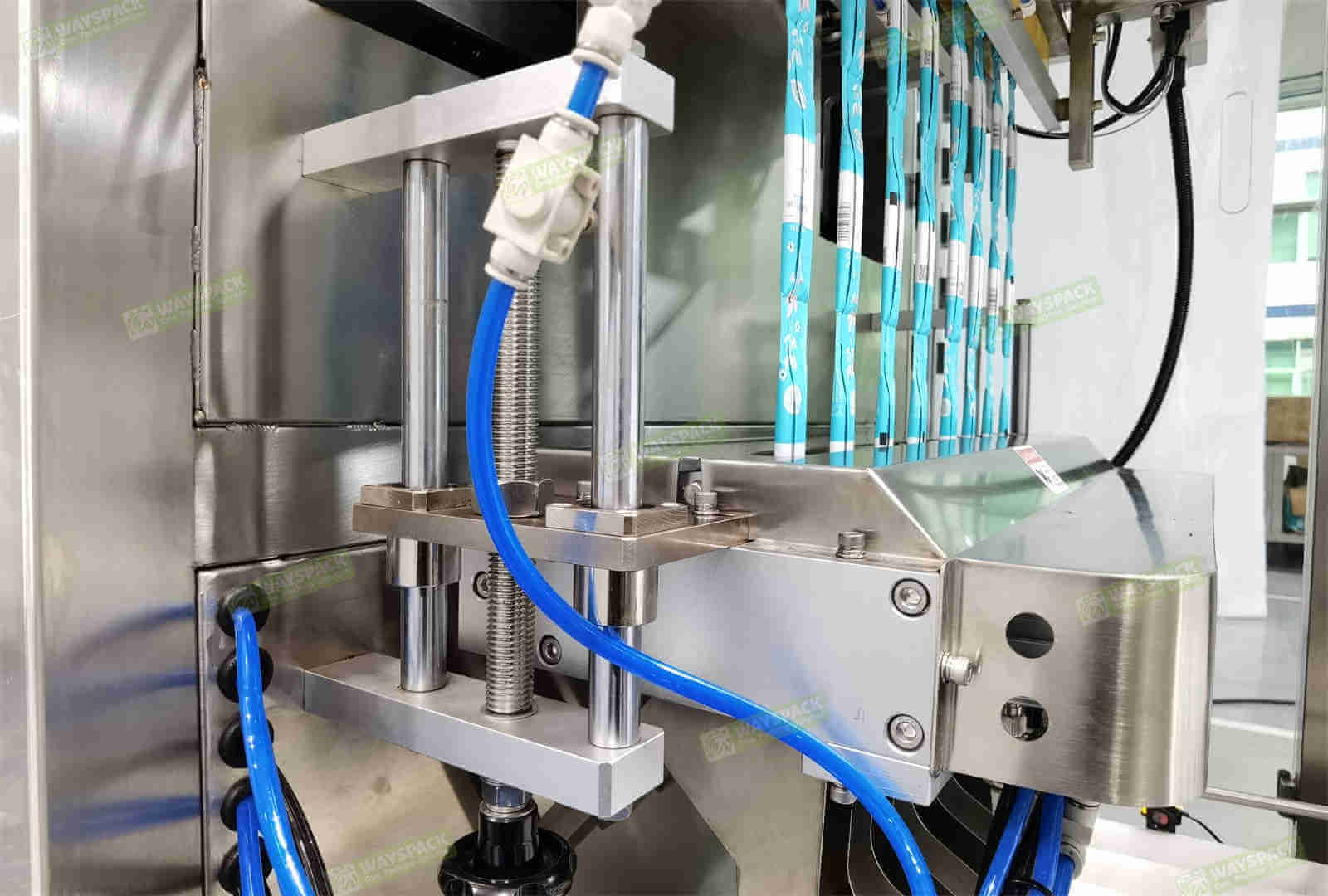

A multi-lane packaging machine consists of the following main components: machine frame, film rolling, bag former, film pulling mechanism, film separating mechanism, middle sealing, end sealing, cutter, PLC, electrical box, etc.

Its main operation process is: installing plastic film – PLC control start – film rolling motor and film pulling motor working – plastic film separating – middle sealing and bag former forming bags – filling in materials – end sealing – cutting.